Polymaker Fiberon™ PETG-ESD is a carbon nanotube-filled (CNT) filament offering electrostatic discharge (ESD) safety with improved toughness making it good candidate for applications in the manufacturing and electronics industry.

Hardened Nozzle Recommended

Hardened Nozzle RecommendedCNT are abrasive.

Ideal Environment

Ideal EnvironmentEnclosure NOT required.

Keep Filament Dry

Keep Filament DryProtect and keep dry with

PolyDryer

Features

-

ESD Safe - Fiberon™ PETG-ESD combines electrostatic discharge (ESD) safety with all-round properties of Tough PETG: ease of printing, heat resistance, durability and strength. Fiberon™ PETG-ESD can be used for a wide range of applications in electronics industry on jigs and fixtures, functional prototyping, electronic housing.

-

Superior Toughness - An excellent choice for engineering applications, Polymaker has introduced its nano reinforcement technology that is featured in all PolyMax™ materials. This boosts the fracture toughness of the ESD material and produces an ESD-safe PETG filament that can still perform in demanding applications. This Industrial PETG ESD filament is ideal for uses such as housings, casings, jigs and fixtures where toughness and electrostatic discharge (ESD) protection is required.

-

Heat Resistant – Fiberon™ PETG-ESD offers fantastic thermal properties with heat deflection temperature of 76°C (0.45 MPa) and Vicat softening temperature of 86°C; suitable for a wide range of practical applications.

-

Surface Finish - Fiberon™ PETG-ESD prints manufacturing jigs and functional parts with a great surface finish. This is partially achieved due to the great fluidity of the PETG filament and the CNT's.

-

Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing, ensure reliable printing and consistency across spools and batches.

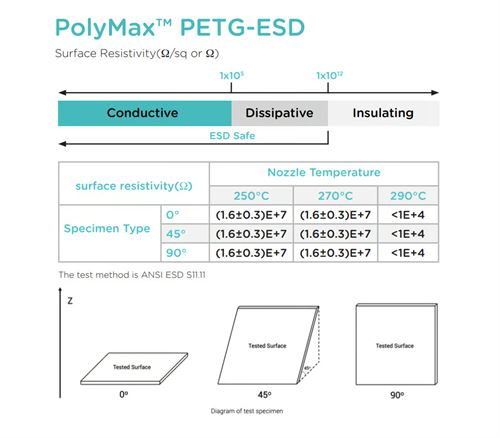

ESD Safety

Ensure PETG-ESD parts are properly grounded to prevent damage to components they may come into contact with. Use materials like ESD mats or grounding cables to allow static charges to safely dissipate.

Technical Data

All PETG-ESD specimens were printed with 290°C nozzle temperature, 80°C bed temperature, cooling fan OFF. Samples were printed with 100% infil, 2 shells and 3 top & bottom layers.

FIBERON PETG-ESD PHYSICAL PROPERTIES

| |

Value |

| Density |

1.24 g/cm3 |

| Melt Index |

14g/10min (280°C, 5 kg)

|

| Moisture Sensitivity |

Moisture Conditioning (70% RH, 23°C)

Equilibrium at 0.41% after 20 days.

Moisture absorption curve. |

FIBERON PETG-ESD THERMAL PROPERTIES

| |

Value |

Testing Method |

| Glass Transition |

77°C |

DSC, 10°C/min |

| Heat Deflection Temperature |

0.45MPa - 76°C

1.8 MPa - 72°C

HDT Curve

|

ISO 75 |

| Vicat Softening Temperature |

86°C |

ISO 306, GB/T 1633 |

FIBERON PETG-ESD MECHANICAL PROPERTIES

| |

Value |

Testing Method |

Youngs Modulus

(X-Y) |

1983 ± 74.9 MPa |

ISO 527, GB/T 1040 |

Youngs Modulus

(Z) |

1626.4 ± 31.5 MPa |

Tensile Strength

(X-Y) |

36.1 ± 0.9 MPa |

ISO 527, GB/T 1040 |

Tensile Strength

(Z) |

20.7 ± 0.6 MPa |

Bending Strength

(X-Y) |

54.0 ± 2.5 MPa |

ISO 306, GB/T 1633 |

Bending Strength

(Z) |

24.1 ± 1.2 MPa |

Charpy Impact Strength Notched

(X-Y) |

5.7 ± 0.5 kJ/m2 |

ISO 179, GB/T 9343 |

Charpy Impact Strength Un-notched

(X-Y) |

29.3 ± 2.2 kJ/m2 |

Data taken from Polymakers Technical Data Sheet and is intended for reference and comparison purposes only. Due to the nature of 3D printing, data should not be used for design specifications or quality control purposes.