Quick Menu

- RISING SUN 3D - ON DEMAND 3D PRINTING

- Ak Interactive

- All Game Terrain

- Ammo by MIG

- Army Painter

- Backpacks and Carrycases

- Bifrost Airbrush Paints

- Coming Soon!

- Connectors

- Chargers

- Gift Cards

- Laser Cutter, Engravers and CNC

- New Items

- Painting Brushes and Tools

- Sale!

- Services

-

- SMS - Premium Acrylic Lacquer Series

- SMS - Pearl Acrylic Lacquer Series

- SMS - Auto Colour

- SMS - Brush Series

- SMS - Cements & Adhesives

- SMS - Colour Sets

- SMS - Colour Shift Acrylic Lacquer Series

- SMS - Crystal Acrylic Lacquer Series

- SMS - DragonAir Airbrushes

- SMS - Effects Acrylic Lacquer Series

- SMS - HyperChrome Series

- SMS - Infinite Colour - Water Based

- SMS - Masking Series

- SMS - Metallic Acrylic Lacquer Series

- SMS - Precision Tools Series

- SMS - Primer Series

- SMS - Thinners, Additives and Paint Remover

- SMS - Weathering Series

- SMS - Wildlife Colours

- STEM

- Trading Card Games

- The Used

- X Class Gear

- Blogs

3D Resin

56 products

Showing 1 - 48 of 56 products

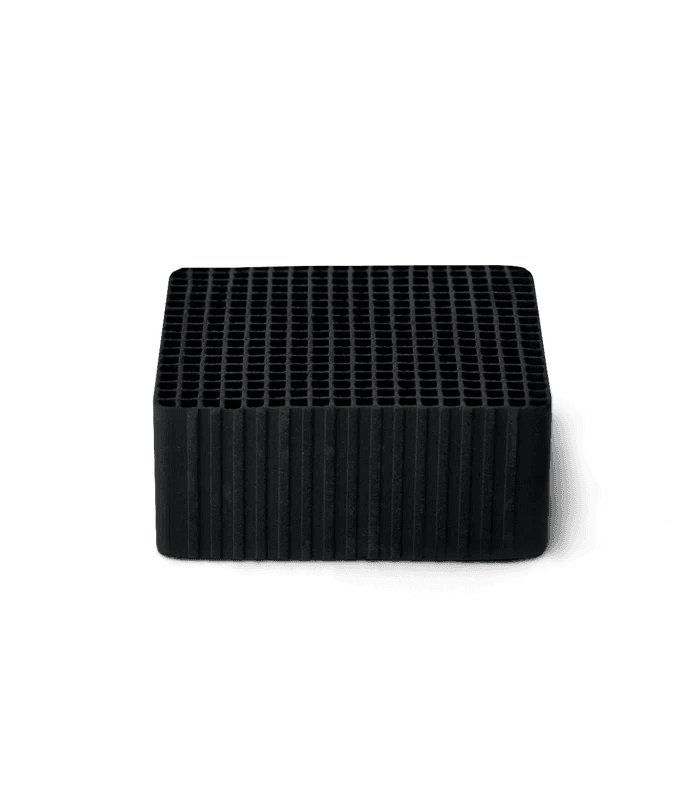

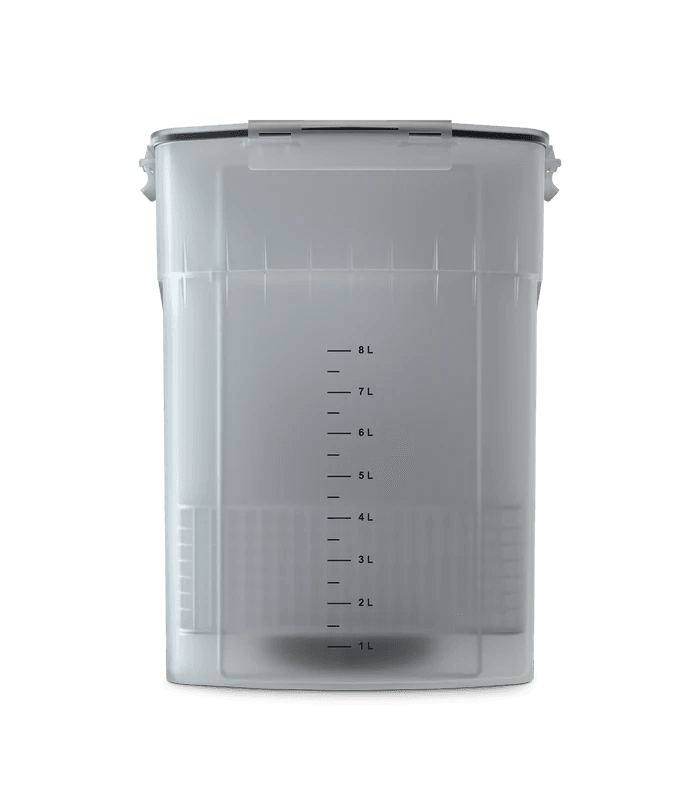

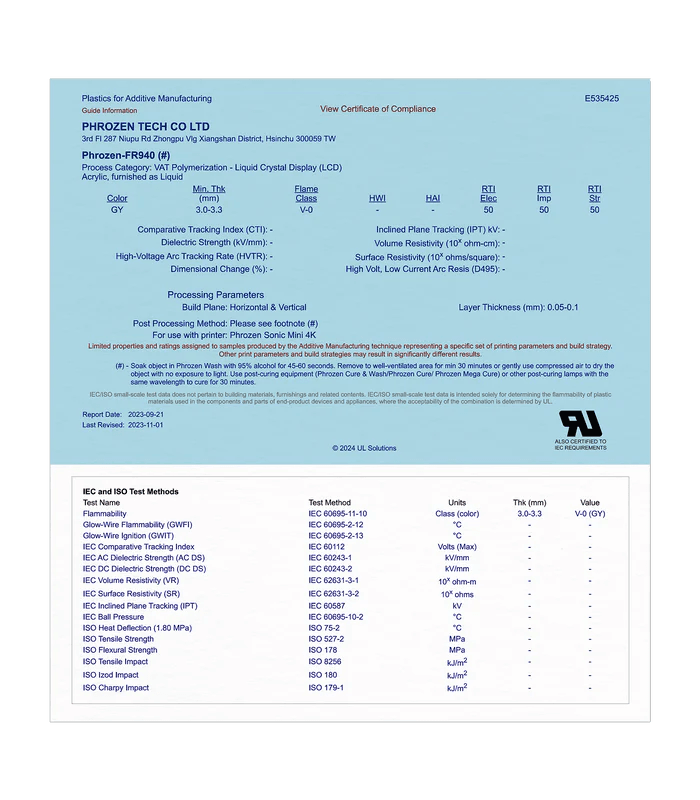

3D Resin – High-Performance Materials for Precision Printing

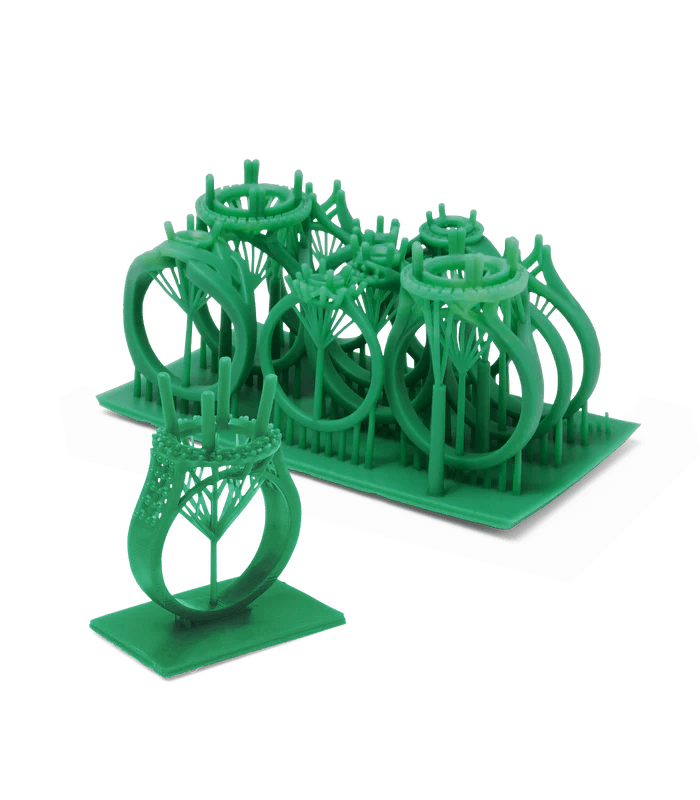

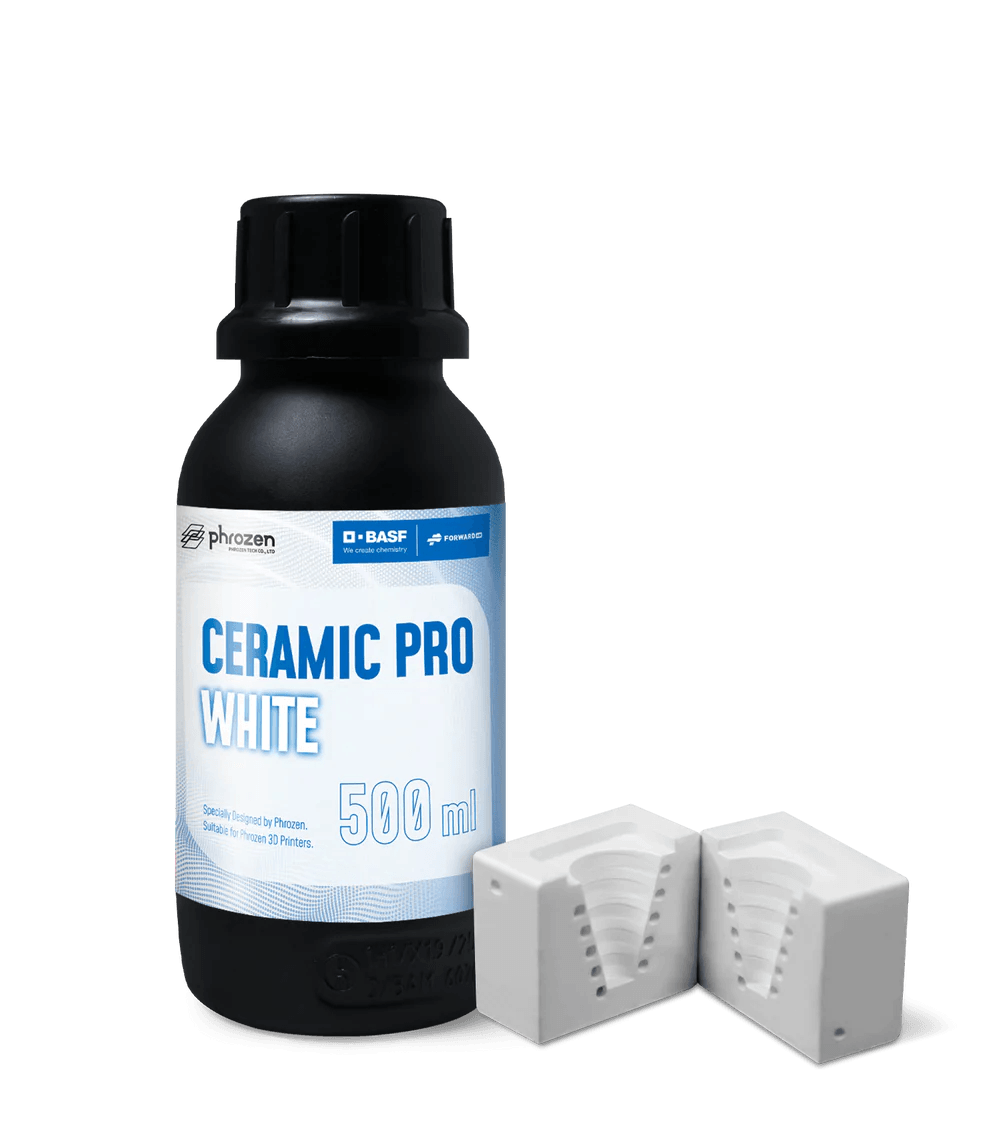

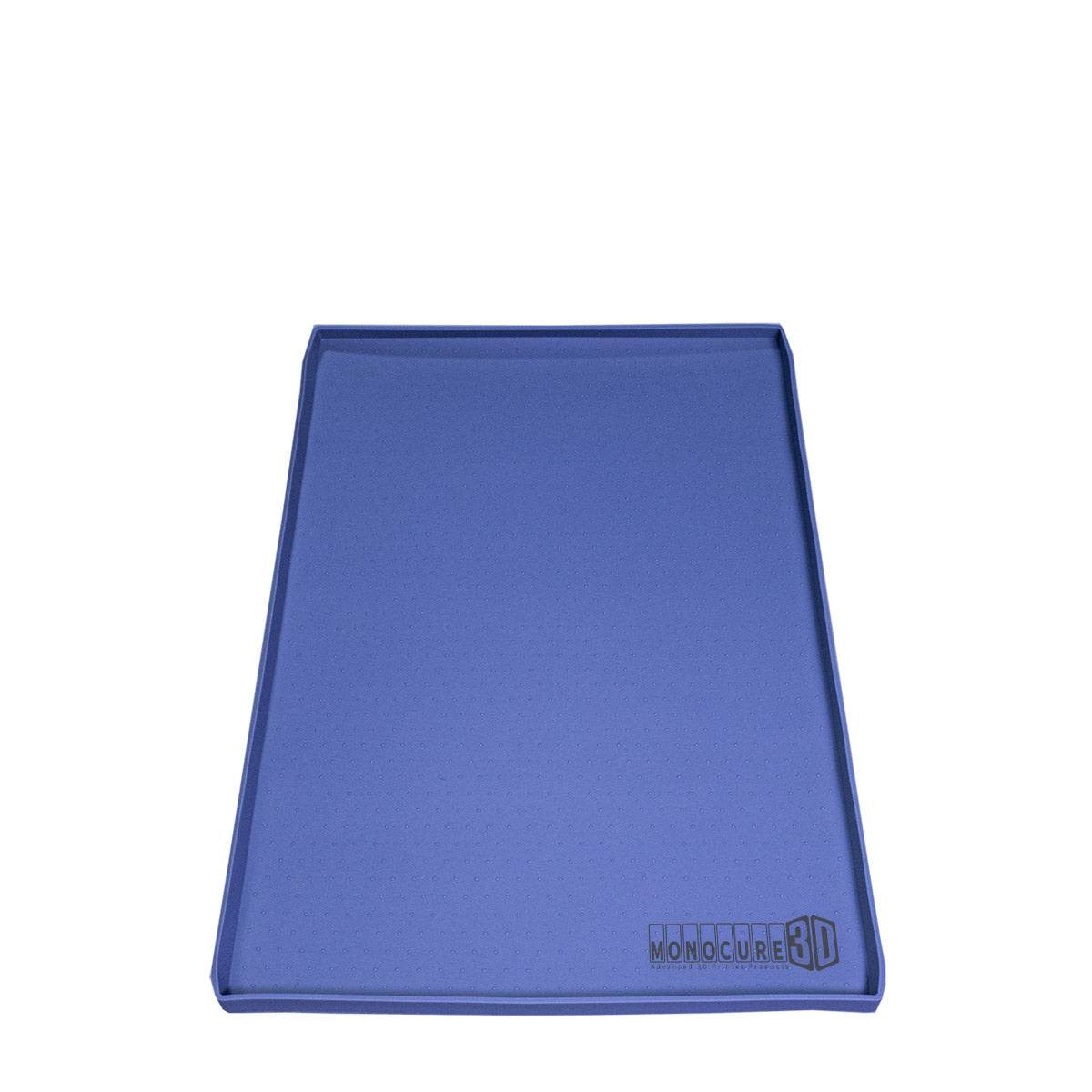

Achieve superior detail, strength, and surface finish with premium 3D resins from Rising Sun FPV. Our 3D Resin collection features a carefully selected range of high-performance resins designed for SLA, MSLA, and DLP 3D printers — perfect for professionals, hobbyists, and businesses who demand exceptional results.

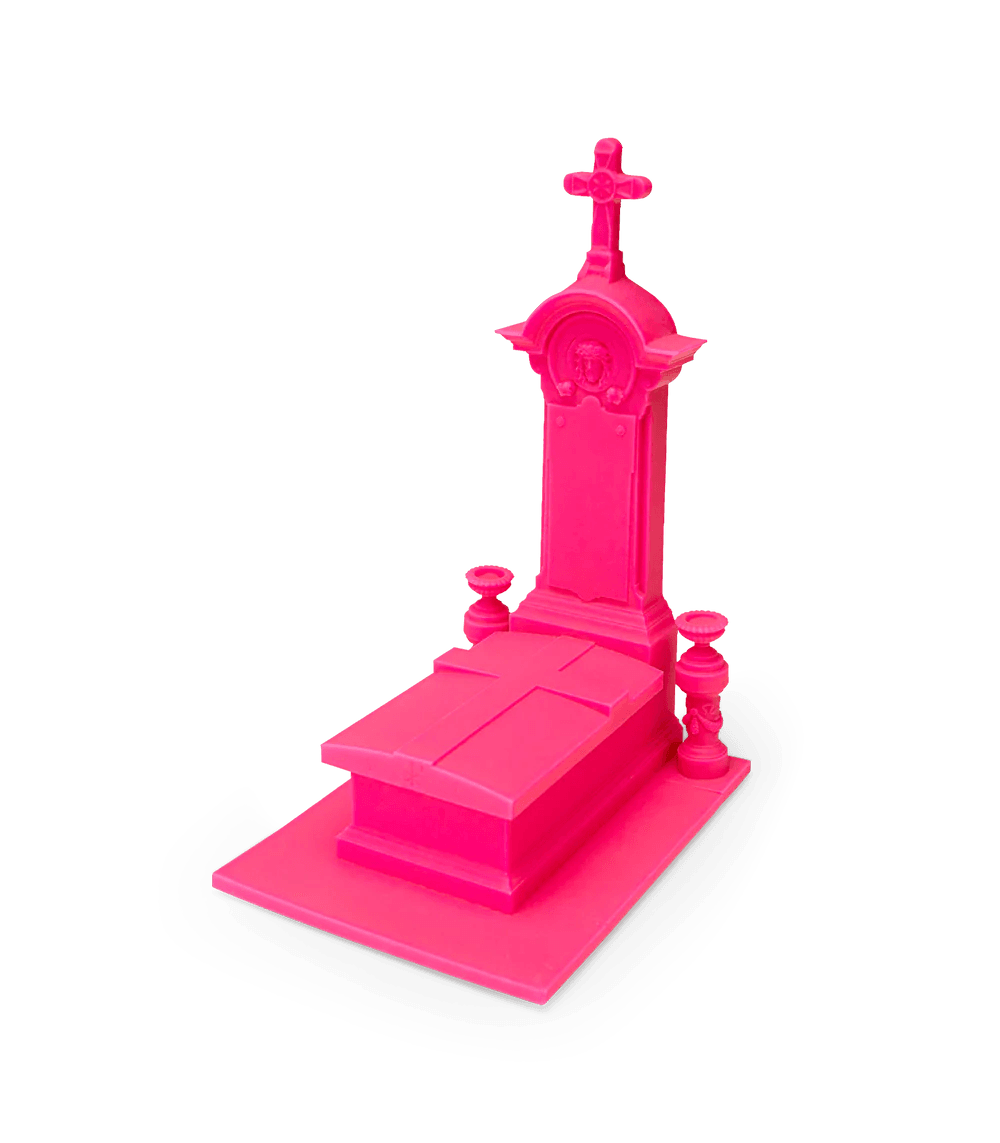

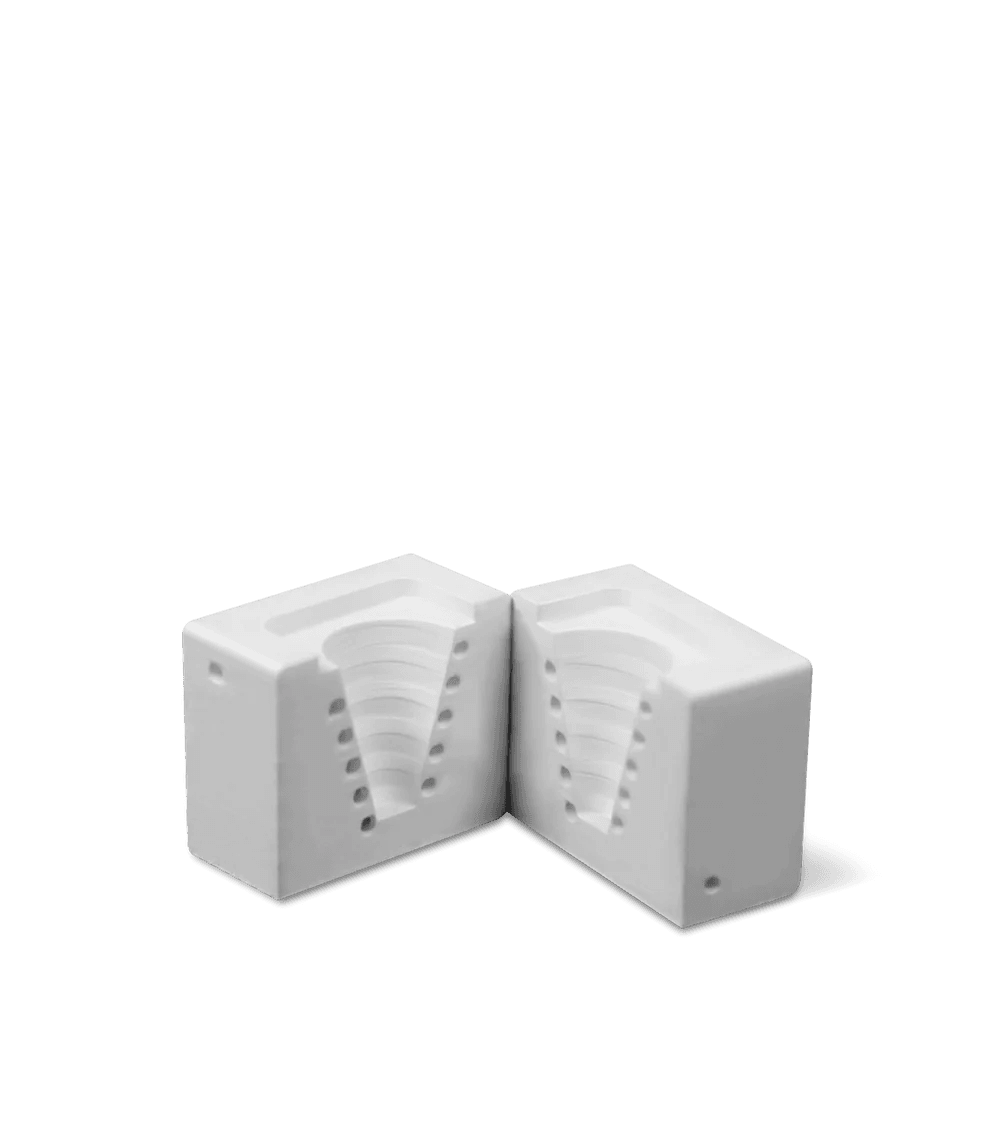

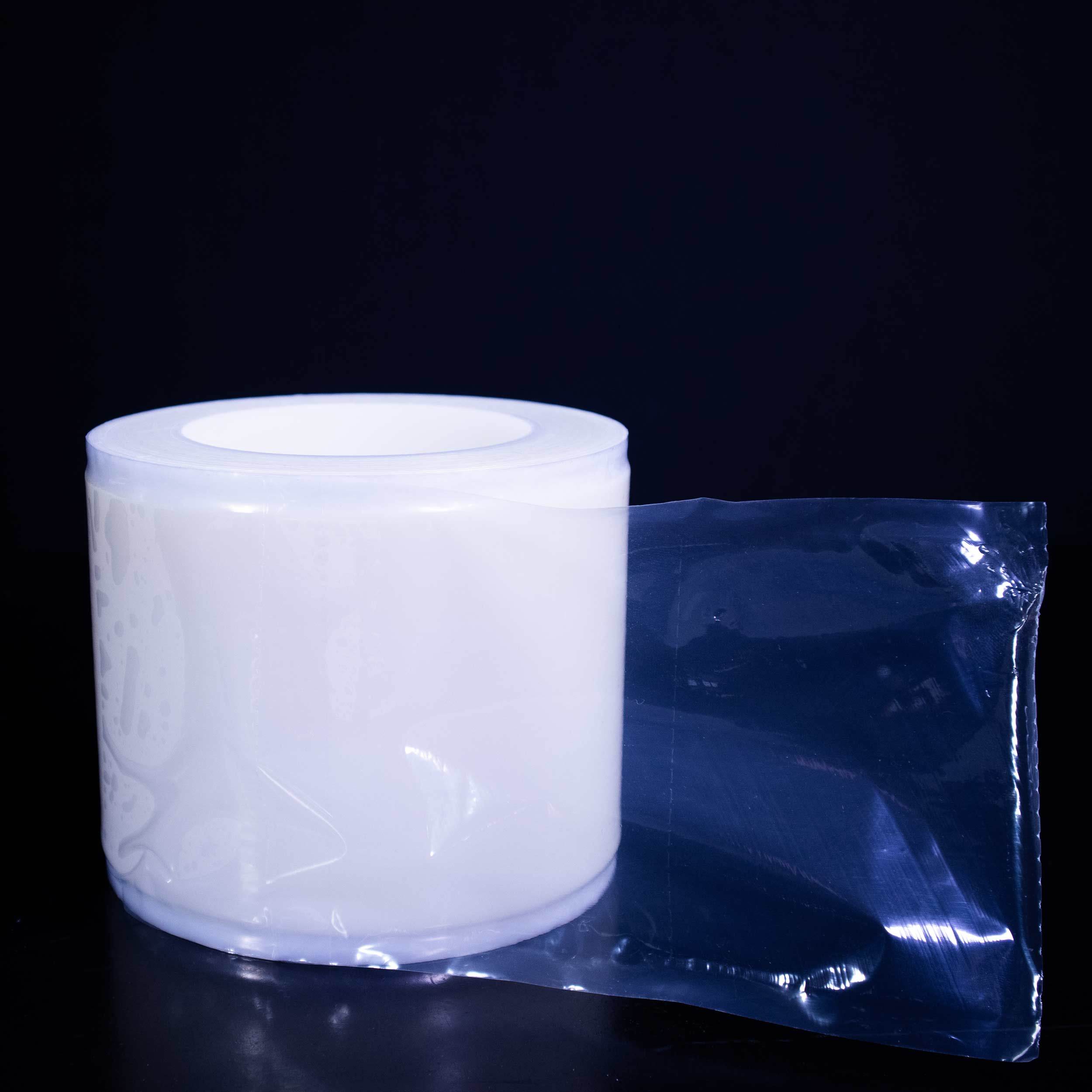

Choose from a wide variety of specialty resins including standard, engineering, flexible, tough, castable, and high-temperature materials. Whether you're printing miniatures, prototypes, functional parts, or intricate models, our resins deliver outstanding accuracy, crisp details, and reliable curing performance.

At Rising Sun FPV, we are committed to supplying Australia's best 3D printing resins with trusted quality, expert advice, and fast local support.

Print with precision — shop our premium 3D resin range today.