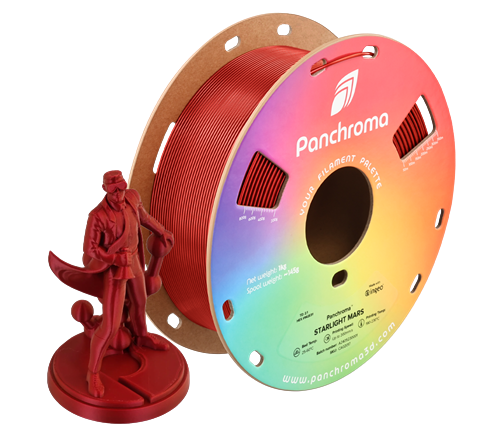

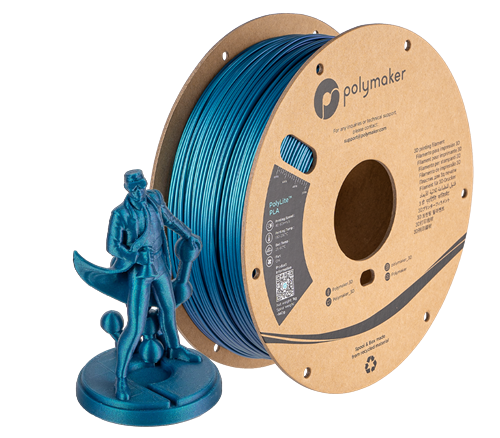

Panchroma™ Starlight PLA (formerly PolyLite™) is a series of high quality PLA filaments with iridescent pigments that reflect colours differently depending on the position of light. Each colour has been formulated to deliver an out-of-this-world effect combining a glittery, shimmery and iridescent surface finish.

Panchroma™ Starlight PLA is based on a high molecular weight PLA from NatureWorks (US raw material supplier) which makes it one of the most rigid PLA materials on the market. The combination of good tensile strength, inter-layer adhesion and stiffness makes Panchroma™ Starlight PLA ideal for product design and prototyping applications that require a rigid material that is beautiful and easy to print.

FEATURES

Shimmery & Iridescent Effect

Panchroma™ Starlight PLA is a high quality PLA with a colour changing pigment that reflects different colours depending on the angle of light. Combined with a glittery and shimmery surface finish that helps to hide the layer lines; Starlight PLA is an excellent choice for astronomy models, science fiction toys, figurines and a wide range of fun and aesthetically pleasing projects.

Wide Printer Compatibility & Jam-Free Technology

Panchroma™ Starlight PLA has been formulated with a very fine colour changing powder that is compatible with standard 0.4mm nozzle, it prints just like normal PLA! Some users have even used 0.2mm nozzle successfully however we consider smaller than 0.4mm to be experimental. Panchroma™ Starlight PLA is compatible with a wide range of 3D printers and works well on most printing surface with a thin layer of glue stick applied, no heated bed is required but can sometimes be used at 40 - 60°C for better results (maximum 60°C).