What is a capacitor?

Written by Team pilot Daniel Harley and Rob Harley

If you’ve been looking at getting into or been involved in FPV drone racing then you would have noticed these things called capacitors that are soldered onto ESC’s and sometimes PDB’s.

What does the capacitor do and why are they used?

Some simplified theory follows but if you don’t like to get too bogged down skim through it, have a look at the rules of thumb below then come back to the theory.

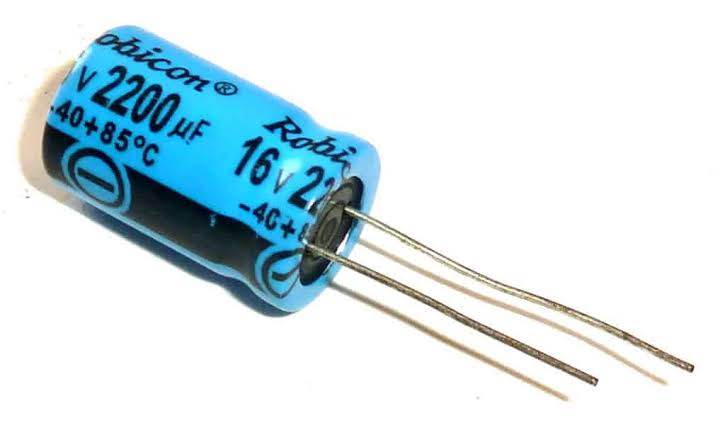

There are different types of capacitor but the most common type you will see and install on your drone is an electrolytic capacitor. An electrolytic capacitor uses an electrolyte (liquid or gel) as a dielectric between two rolled up plates of metal, usually aluminium, that is then placed into a small cylinder. Electrolytic capacitors have high capacitance for their physical size and are polarised, i.e. they have positive and a negative side, but have some drawbacks like deterioration with heat, loss of electrolyte etc.

A capacitor is a device that stores electrical energy but unlike a battery does not itself generate energy. They are placed in an electrical circuit to smooth out fluctuations in voltage levels. They absorb and release energy as the circuit current demand changes.

To be the most effective capacitors need to be placed as close as possible to the switching circuit in the ESC (FET’s). The FET’s effectively are a switch that turns the battery supply on and off very quickly to create an alternating current of varying frequency to drive the motors. Turning this current on and off very quickly causes a large current and then a low current to flow in the battery wires cyclically, this causes a magnetic field to build up and collapse around the battery wires causing large voltage spikes to be generated. The capacitor is used to absorb the high voltage spikes during the low current time and then release that energy when high current is required. It needs to be as close as electrically possible to the FET’s with as low resistance as possible. At this point you're probably thinking, don’t ESC’s already have capacitance built in, why do we need more? The ESC’s certainly do have capacitors built in (they are needed for the circuit to work), they are board mounted and are much better than external capacitors as they have lower ESR but usually only just have enough capacitance installed to keep the board size small, keep costs down etc.The longer the battery leads are from battery to ESC input the more important this capacitor becomes to protect our expensive FETS on the ESC. As the lead length is increased the more pronounced the effect of the building up and collapsing of the magnetic field has around the wires, and the greater the spike voltages will be. This effect is known as inductance.

This effect is more problematic in Beast / X-Class drones because the currents are much higher, induced magnetic fields are higher so voltage spikes (noise) are much higher.

What happens if we don’t use them?

If we don’t use external capacitors the ESC will function OK, but we are risking degradation of the ESC over time as the spikes need to be handled by the onboard capacitors, increasing their temperature, and shortening their lifespan. If battery lead lengths are long the onboard capacitance will be insufficient to deal with the increased noise.

In the case of the very high battery and ESC currents of Beast and X-Class there really is no option you should use external capacitors on your expensive ESC’s or run the risk of a very short ESC lifespan. The lead length from ESC to motor doesn’t really matter as the winding inductance of the motors smooths out the current spikes on the output side, but LiPO to ESC length is critical on the ESC input side and needs to be as short as possible.

How do we reduce this inductance effect and therefore reduce the input voltage spikes and noise?

Rules of Thumb:

- Keep LiPO to ESC length short, this includes the length through the tracks of any PDB

- Keep the LiPO to PDB and the PDB to ESC wires as close together as possible, run them taped together side by side or preferably twisted together to reduce inductance.

- Add capacitance to ESC input, use as short a lead on capacitor as possible to further reduce any inductive and resistive effects.

- Make sure positive and negative leads are connected the right way around, electrolytic capacitors are polarised.

Capacitors have a number of ratings but the most important for us are:-

Capacitance - the ability of a component to collect and store energy in the form of an electrical charge.

Voltage - The maximum voltage that the capacitor can withstand before breaking down and failing

ESR - Equivalent Series Resistance - a measure of the electrical resistance that the capacitor exhibits during operation.

How much capacitance do we need?

For a typical small quad with a 4 in 1 ESC use a 470uF to 1000uF, (680uF is a good choice)

For seperate ESC on small quads use around 220uF to 330uF on each ESC.

For beast class and X-Class use the ESC manufacturer recommendation for example APD state “Low-ESR 330uF-1000uF must be used on the ESC inputs if your wiring is longer than 12cm”

In all cases make sure that the voltage rating of the capacitor is higher than the system voltage.

The following voltage recommendations are conservative, but have a margin of safety.

4S - use a capacitor with voltage rating of 35V or higher.

6S - use a capacitor with voltage rating of 50V or higher.

8S - use a capacitor with voltage rating of 63V or higher.

12S - use a capacitor with voltage rating of 80V or higher.

You could use a lower voltage capacitor in each case but run the risk of reduced capacitor lifetime in high noise ripple current environments.

In all cases make certain that the capacitor is a low ESR model. Low ESR capacitors will run at cooler temperatures, perform better at spike and ripple filtering and overall are a much better choice in this application. They are also more expensive.

Do capacitors wear out?

Yes electrolytic capacitors deteriorate over time and should be replaced regularly. In Beast and X-Class applications which are very demanding on a capacitor, The APD recommendation is that “Capacitor performance drops over time, so change them every 20-30 flights, even if they look ok”.

There are many good brands of capacitor but some of the better low ESR high ripple current handling ones are:

- Rubycon ZLJ or ZLH series

- Panasonic FM & FS series

1 comment

Martin

Thanks Zak. Very useful indeed. Did not realise I should be on 80 volt for 12S. All very clear and precise. Cheers, Fossil.